Cool Moulds, Hot Results

Metal Additive Manufacturing

Metal Additive Manufacturing

Advanced Mould Tools - Proudly Made in the UK

Problem Statement

In the vast landscape of manufacturing, the tooling sector stands out for its unique challenges and dynamics. While many industries have seamlessly integrated innovations such as metal 3D printing (also known as Selective Laser Melting), the tooling sector’s adoption of advanced manufacturing has been throttled by high costs that are often associated with using these technologies.

The primary challenge is the complex balancing act of cost and innovation. This case study demonstrates that economic pressures no longer need to eclipse the immense technical benefits that advanced manufacturing, with Apex Additive Technologies, promises.

We set out to answer the following questions:

- Cost Comparison: Can a metal 3D printed mould insert compete financially with its traditionally manufactured counterpart?

- Lead Time: What’s the production speed of a metal 3D printed mould insert versus traditional methods?

- Pressure Resilience: Can 3D printed moulds sustain the clamping pressures inherent in injection moulding processes?

- Efficiency Evaluation: Does conformal cooling offer tangible benefits for the injection moulding process?

- Leakage Concerns: Prior experiments with conformal cooling encountered leakage issues. With advancements in technology, can the integrity of these channels be assured?

- Comparison with Industry Standards: How do the mechanical properties and hardness of 3D printing materials compare with the trusted standards of P20 and H13 tool steels?

- Tool Longevity: What is the expected durability and lifespan of 3D printed tools relative to their traditional counterparts?

Our Approach

-

Design & Simulation

Part Design & Simulation

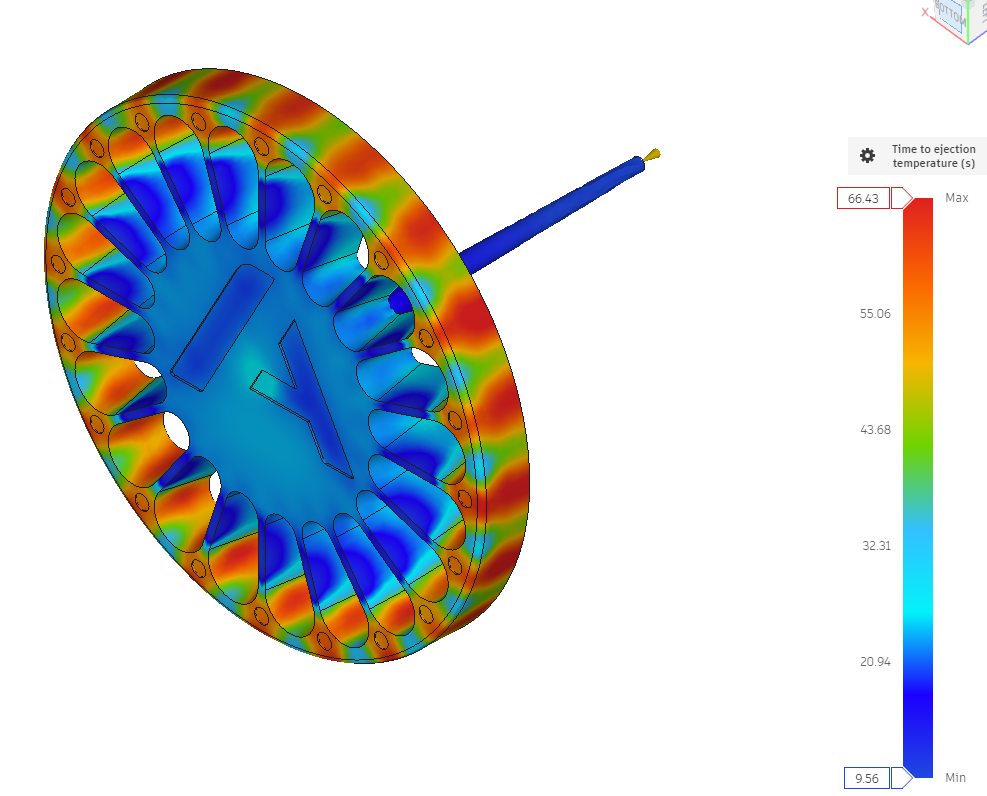

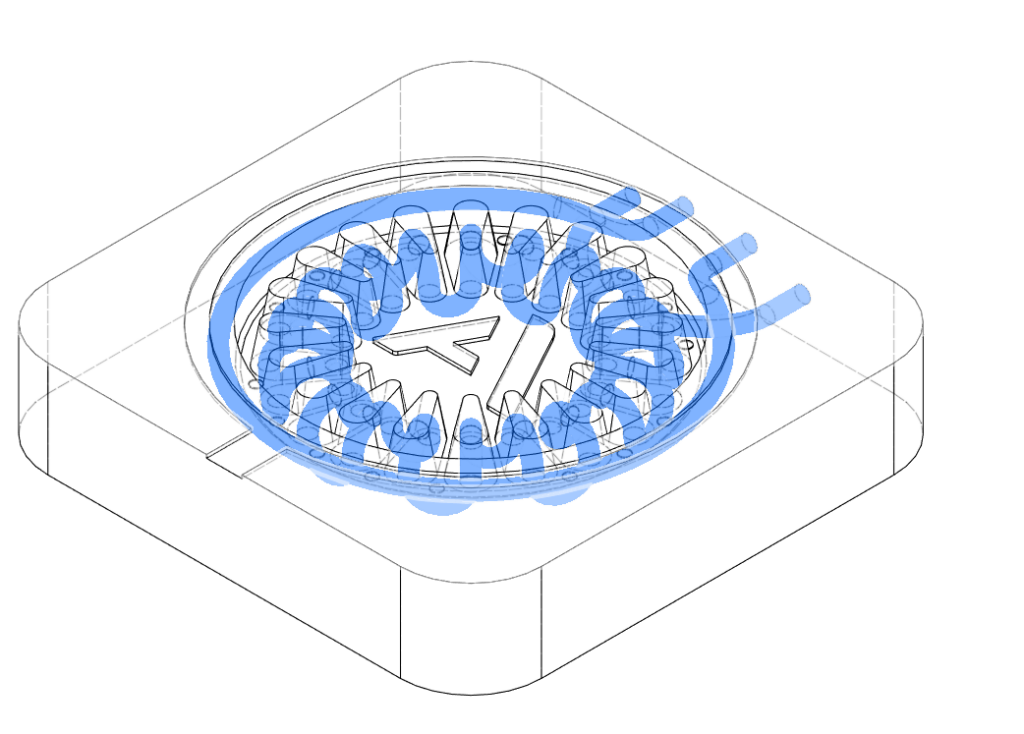

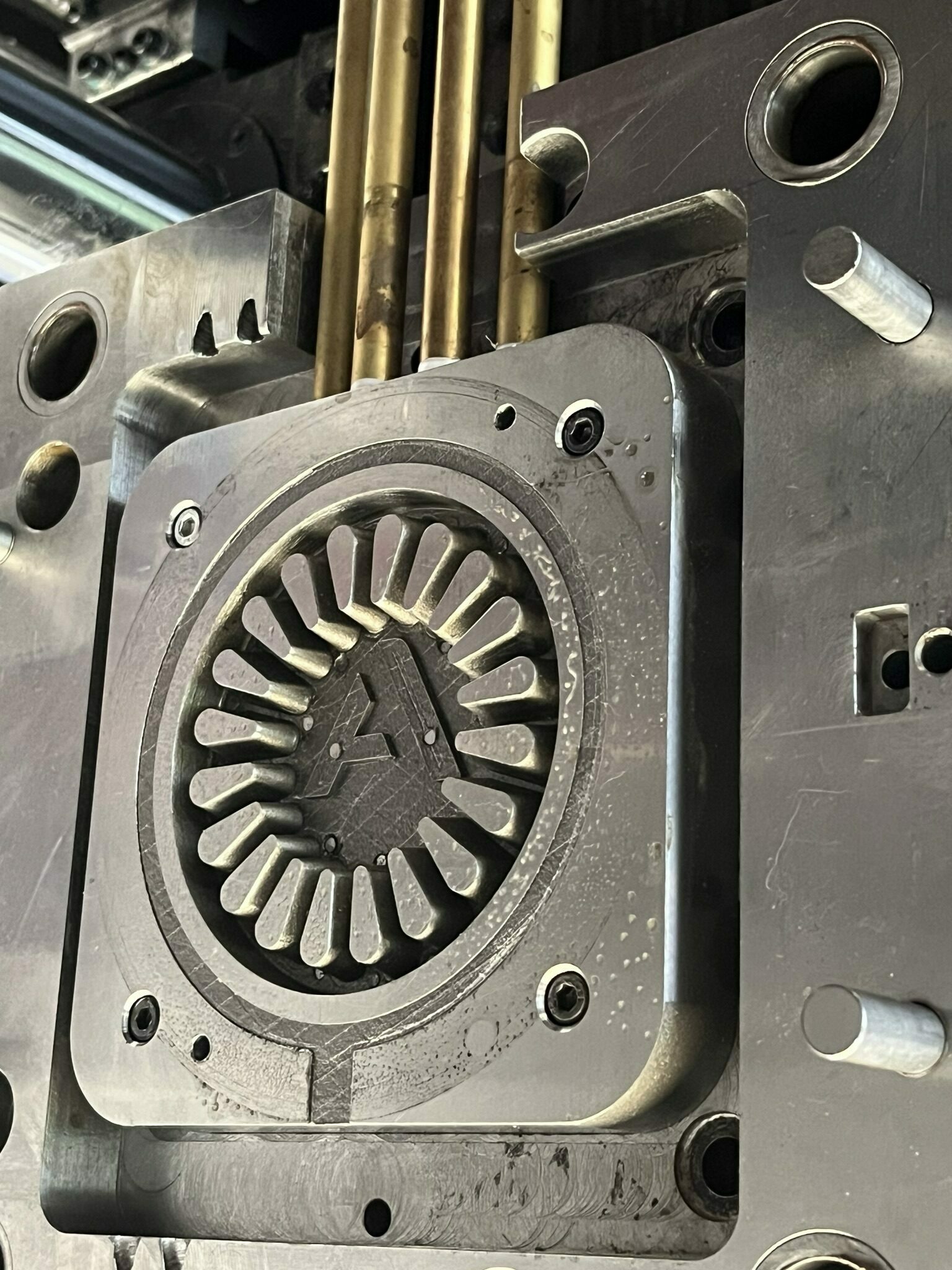

A simple coaster was conceived to be injection moulded using inserts printed via selective laser melting technology at Apex’s state-of-the-art facility in Wales. The design and simulation were executed in Autodesk Fusion360, leveraging Autodesk’s extensive library of plastic materials and processes.

The simulation results predicted a time to ejection >60 seconds for a PVC using default injection moulding settings.

With conformal cooling the predicted time to ejection was 33 seconds.

-

Advanced Manufacturing (Metal 3D Printing)

Advanced Manufacturing:

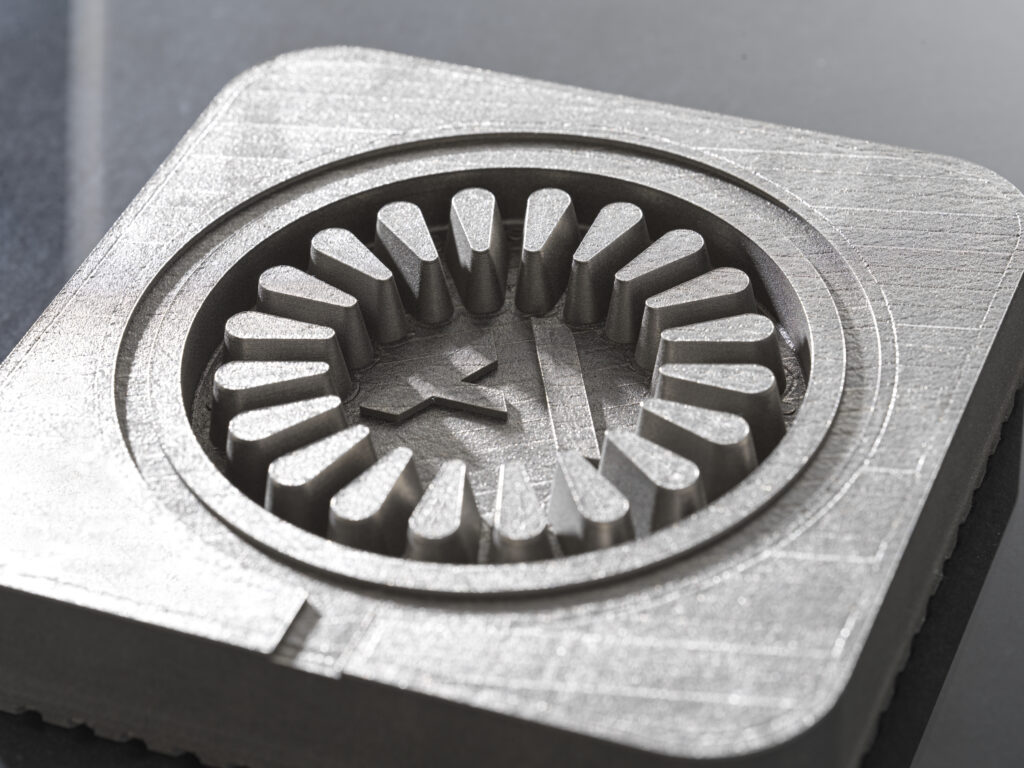

Our Renishaw 500Q multilaser system was employed to print the parts, in Maraging Steel – M300 (DIN 1.2709), using Apex’s proprietary laser process parameters and scanning strategies, to expedite the printing process without compromising the quality.

The printed mould inserts were scanned using our Hexagon AS1 optical metrology system, confirming a maximum deviation from the CAD design below 220um in the as printed condition.

The inserts were then heat treated using our vacuum furnace using our proprietary heat treatment cycle to gain the required material hardness and removed from the plate using our GFMS CutAM 500, rapid wire EDM system

Finishing:

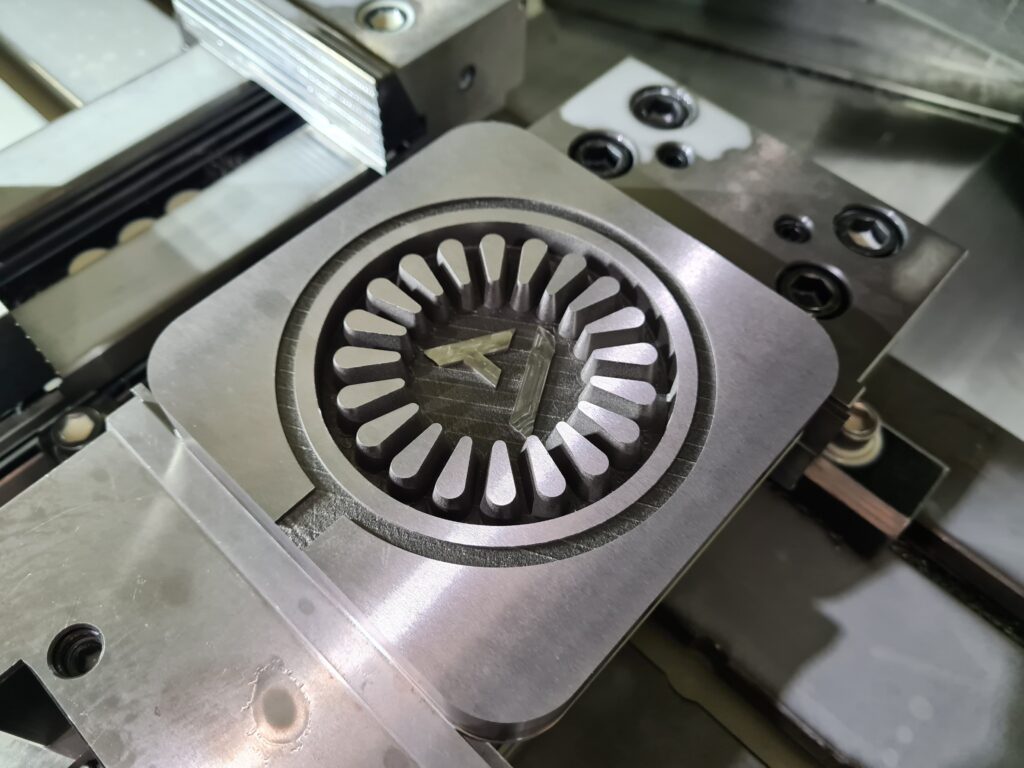

The parts were 5-axis CNC machined to tolerance to ensure satisfactory shut off between the cavity and core.

-

Injection Moulding

DB Moulding took charge of the injection moulding process. Their findings indicated a substantial 47% reduction in moulding cycle times with the conformally cooled inserts. The cooling channels exhibited no leakage, and the inserts held their ground under 90T clamping force.

-

Conclusions

The crowning achievement was the drastic reduction in lead time—from design to commission, the entire process was completed in just 12 days. This efficiency translated to a 40% cost-saving compared to imported inserts which would not have the conformal cooling channels.

- Cost Comparison: 40% Cheaper

- Lead Time: 12 days from Apex vs 3 months for imports

- Pressure Resilience: 90T Clamping Pressure

- Efficiency Evaluation: 47% reduction in moulding cycle time

- Leakage Concerns: No leaks from conformal cooling channels, thanks to Apex’s proprietary laser processing parameters

- Comparison with Industry Standards: Mechanical properties comparable to P20 and H13

- Tool Longevity: Watch this space for our work on engineering microstructures to tailor the hardness levels to your needs!

Advanced manufacturing unlocks significant advantages to the tooling sector. Advanced manufacturing with Apex will break the cost barriers for your business – that’s our promise.