Medical Excellence with Aerospace Precision – CMF Implants

Metal Additive Manufacturing

Metal Additive Manufacturing

Craniomaxillofacial Implants (CMF) - Proudly made in the UK

At Apex Additive Technologies, we bring the discipline of aerospace engineering into the service of medicine. Our mission is to deliver CMF implants of unrivalled quality at unbeatable prices—not by taking shortcuts, but by relying on pure science, materials mastery, and engineering expertise. Every implant we make embodies precision, safety, and reliability, ensuring the best outcomes for patients and the surgeons who care for them.

Our Approach

-

Superior Material

Our implants are manufactured exclusively from the highest quality Ti-6Al-4V Gr23 ELI powder, processed under conditions that eliminate contamination risks. Through zero-oxygen processing and strict moisture control, we ensure purity from powder to part.

After printing, every implant undergoes vacuum heat treatment (inhouse)—a process that prevents the formation of alpha case, the brittle surface layer that can compromise fatigue resistance. Apex’s proprietary thermal treatment tailors the alloy microstructure to achieve both strength and ductility, optimising fatigue performance while enabling up to 20% elongation—a rare achievement in medical-grade Ti-6Al-4V.

-

Custom Finishes to Engineering Requirements

Surface integrity matters not only for implant integration but also for surgical handling. Apex offers three surface finishes, each validated through Ra surface roughness measurements:

-

Smooth finish (Ra 0.8um): engineered to be smooth enough for safe surgical handling.

-

Satin finish (Ra 0.35um): our recommended option—low Ra values with a tactile surface that will not pinch surgical gloves.

-

Polished (Ra 0.3um): available on request, but rarely necessary. As per customer feedback, polishing for appearance alone is a cost-additive process without clinical benefit.

By eliminating unnecessary steps, we keep costs down without compromising function, ensuring surgeons receive implants that are both practical and affordable.

-

-

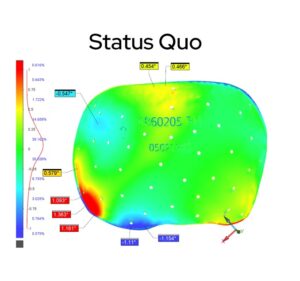

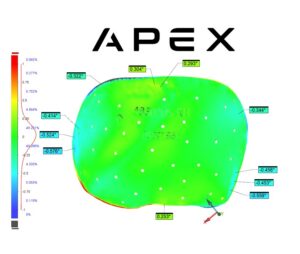

Aerospace Precision

Implant fit is a distinguishing measure of quality. At Apex, our geometrical compliance is unmatched thanks to rigorous control of the Laser Powder Bed Fusion (LPBF) process and advanced distortion compensation strategies.

Where others deliver “near net shape,” we deliver true net fit. By predicting and compensating for the subtle distortions inherent in LPBF, our implants achieve a level of conformity that surgeons consistently describe as “like no other.”

The result: implants that seat precisely, align intuitively, and restore patient anatomy with aerospace-grade accuracy. This is not a claim—it’s something you must try to truly appreciate.

-

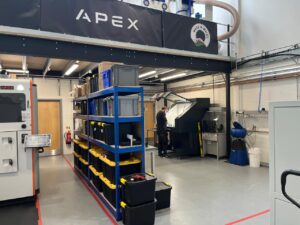

Made in the UK – Quality Without Compromise

All implants are designed, manufactured, heat treated, finished, and inspected under one roof in Wales. This vertical integration guarantees:

-

Full control of quality across every stage.

-

Short lead times, ensuring patients are never left waiting.

-

Excellent customer service, with direct communication between surgeons, engineers, and production teams.

Traceability & Transparency

Every implant is accompanied by a fully traceable job card, accessible to customers. From powder batch to final inspection, the entire process is transparent—something few can offer, and none at our price point.

-